Choosing The Correct Compressor

A diesel engine mobile compressor is required for an abrasive blast machine. Choosing the right sized compressor is vital in reducing downtime and increasing productivity rates. A compressor sized too small will not provide enough air to the machine leading to poor blasting results and overworking the compressor. Always aim for a slightly higher rating than you will need.

The compressors CFM (cubic feet of air per minute) output is an important factor when choosing a compressor. Large CFM compressors will allow for satisfactory air supply to both the blast vessel and the operators safety air fed helmet.

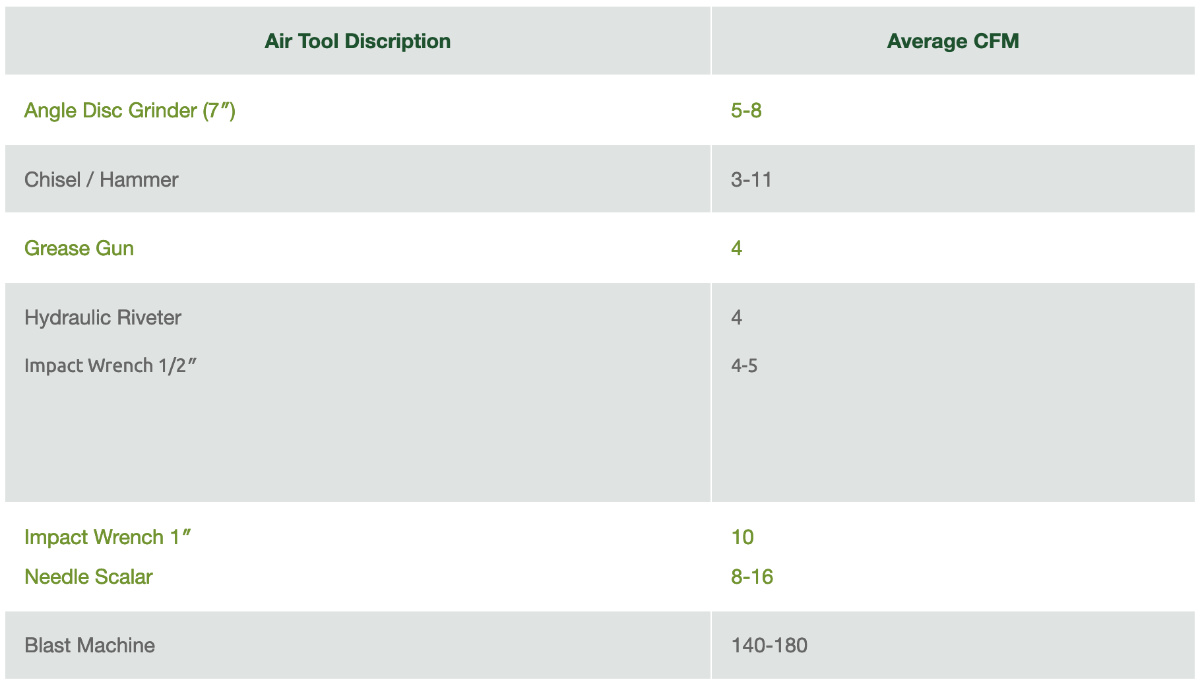

To give you an idea of what CFM a blasting machine will require is an average CFM rating for common air tools below:

140 CFM: A 140 CFM compressor is the lowest CFM compressor that should be used as their cleaning rate with a blast machine is relatively slow; therefore a compressor under this rating would be insufficient. This size compressor would be ideal for a user that requires maneuverability and adequate air supply for small to medium sized projects.

180 CFM: Compressors of this size would be most suited for blasting as they offer maneuverability and a comfortable delivery of free air . This size compressor will allow for blasting projects of medium scale such as blasting car shells, tractors and trailers.

260 CFM: This popular sized compressor is more than enough for an abrasive blasting business as it can be used for small to large scale projects with ease. Compressors of this size allow for long lengths of hosing with minimal power loss.

350 – 500 CFM: This type of compressor would be required where fast cleaning rate is required for large-huge scale projects such as building steelwork, ship hulls, trains and concrete apartment blocks. These compressors are much more difficult to maneuver and require a powerful van/jeep to move.