A Highly Efficient Air Operated Recovery System For The Rapid Recovery, Cleaning & Recycling of Blasting Abrasives

The Applied Classic Grit Recovery System is an innovative, highly efficient air operated grit recovery system which utilises a compressed air stream to recycle the abrasive back into the blast machine while extracting the dust.

With low initial cost, this versatile and innovative grit recovery system has proved to be an essential piece of kit for small and large blast rooms alike.

Optimal Solution

Recovering abrasive blast media can significantly reduce your blast media costs. The use of an Applied Classic Grit Recovery System, combined with recoverable blast media, can provide a substantial return on investment. Reusable media are also faster acting and less dusty, which translates to increased productivity and a cleaner work environment.

Recycling blasting abrasives also saves money by reducing waste. An economical alternative to full-floor mechanical recovery systems, the Applied Classic Grit Recovery System can be installed in an existing blast room or ordered with a new blast room.

Easy to set up and use, the Applied Classic Grit Recovery System allows blast operators to work until significant media builds up on the floor of the blast room. Operators then simply sweep the abrasive into the hopper, using a brush, shovels, compressed air, or a forklift brush. The media is then pneumatically transported up, cleaned, and returned to the blast pot.

The system automatically cleans recyclable abrasives and returns the clean, good media back to the blast machine.

Media Recovery Rates

This system is designed to recover up to 1,000kgs of blasting media per hour.

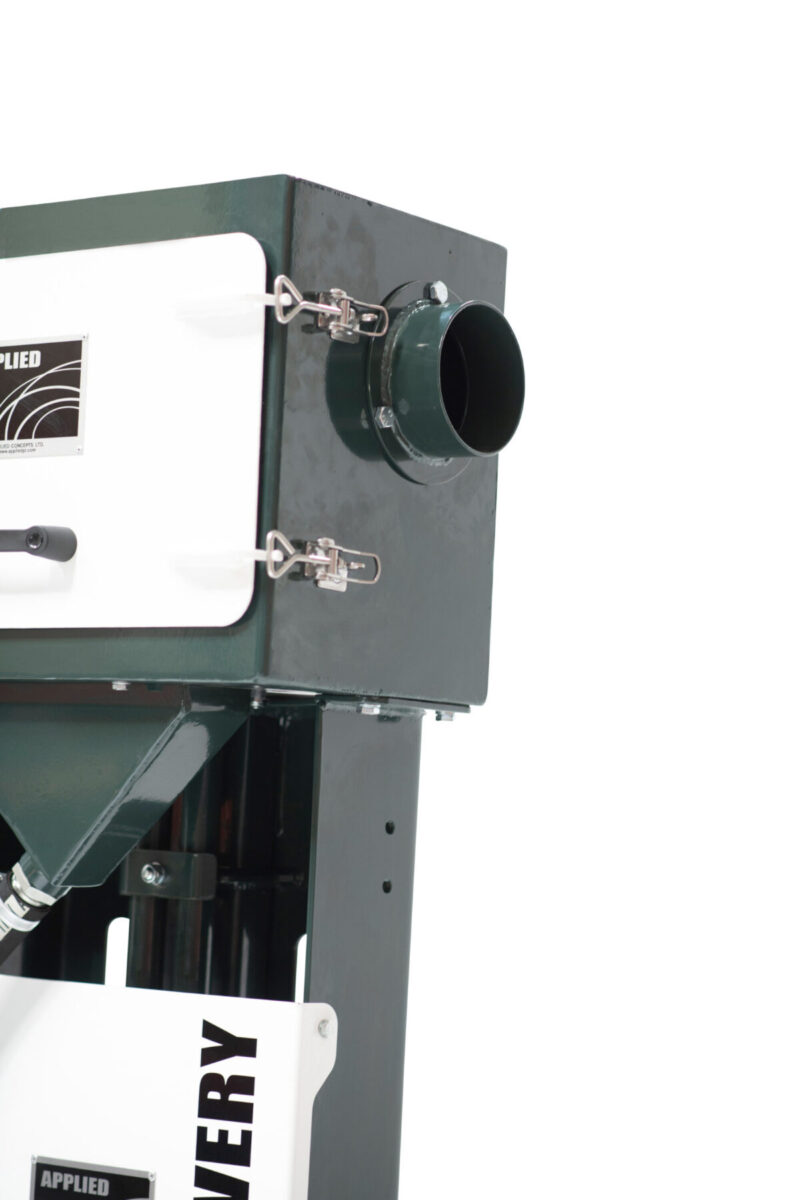

How It Operates

The spent abrasive is swept into a small hopper sunk into the blastroom floor, which is equipped with a cover grille to prevent oversized abrasive media from entering the system. The abrasive is pneumatically lifted through the elevator pipes where the system then filters out the fines particles, via an air wash from the dust extraction unit. The cleaned abrasive is then gravitationally fed to the blasting machine.

Minimum air requirement: 50 CFM at 30 PSI .